Nrv50 Equipped With Torque Arm Worm Gear Worm Shaft Aluminum Shell Reducer

As one of the torque arm manufacturers, suppliers, and exporters of mechanical products, We offer torque arms and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of the torque arm.

Installation process of the worm gear and worm reducer torque arm

Note) Please avoid connecting the reducer with the input two shafts to the main shaft for installation.

(1) Please use bolts to install the torque arm on the reducer.

Note) If a torque arm is ordered, use the attached bolt. If a customer makes their torque arm, use bolts equivalent to strength category 10.9.

(2) Please insert the reducer into the driven shaft.

(3) Please fix the reducer to the driven shaft in the direction of the shaft.

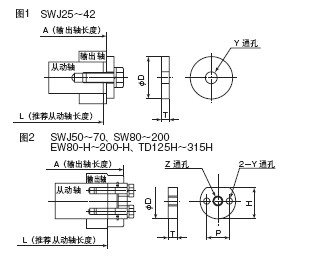

When SWJ25 ~ 42, fixing it to the output shaft through the end plate is recommended, as shown in Figure 1 End.

◎ When SWJ50-70, SW80-200, EW80-H ~ 200-H (hollow output type), TD125H ~ 315H, it is recommended to use the output as shown in Figure 2

The hollow shaft is a retaining groove, and the stop ring and end plate are fixed. (Refer to page 217 for detailed dimensions of the hollow output shaft)

(4) After the installation form of the reducer is determined, please fix the torque arm to ensure that the reducer and driven shaft will not rotate simultaneously. Please make the torque arm have a certain degree of freedom in the axis direction.

Note) If you fix the torque arm before settling the reducer, the reducer may be damaged, so follow the work process. After selecting the hollow output shaft and driven shaft, please set the position of the bearing supporting the driven shaft. (EW80-H to 200-H is the base installation.

Note) The dimensions and shapes shown in Table 1 on the next page are recommended for making end plates so they can double as removal plates.

Manufacturing Plant

Application

Packing & Delivery